Customer Services

Copyright © 2025 Desertcart Holdings Limited

🛠️ Extract with confidence, every time!

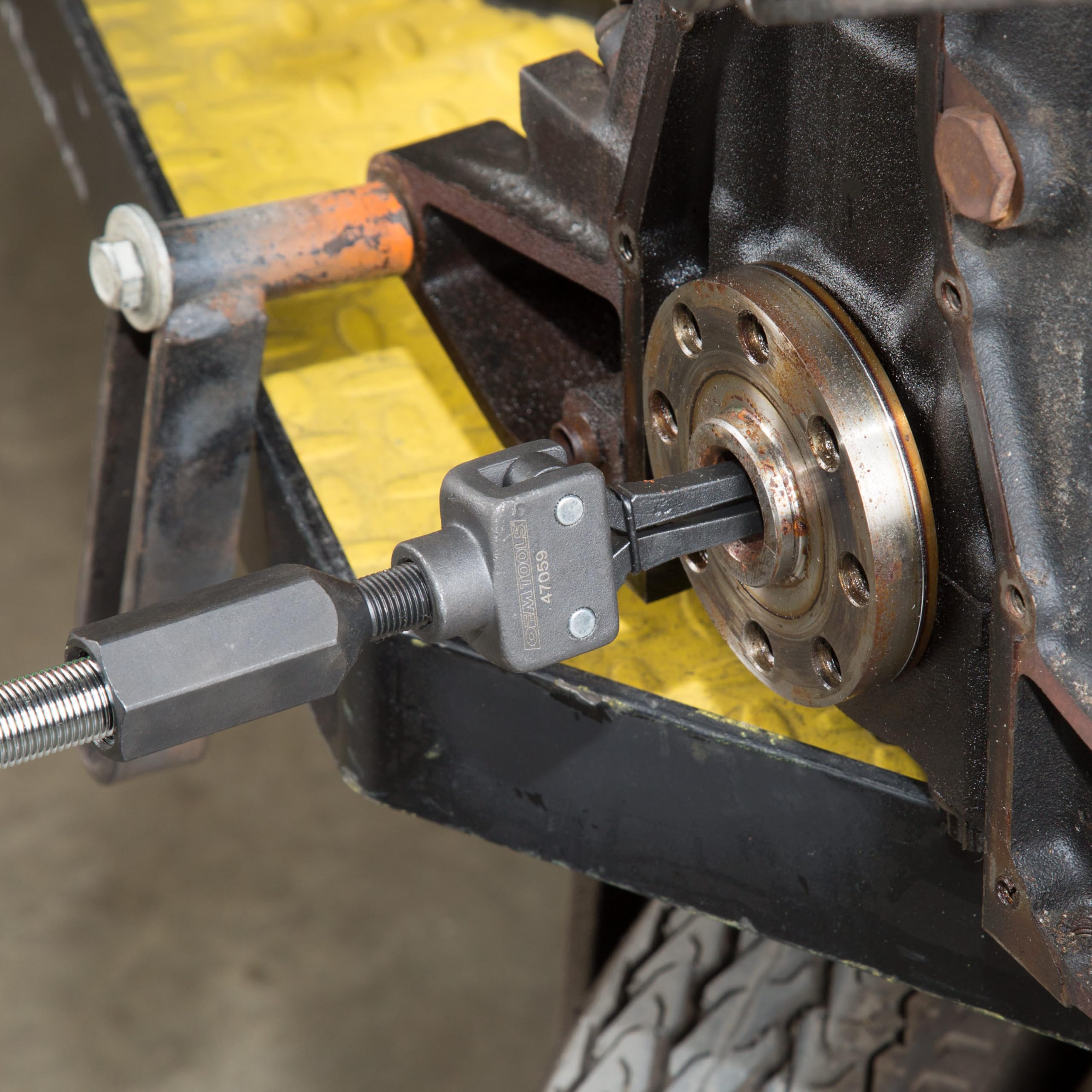

The OEMTOOLS 27059 Pilot Bearing Puller Attachment is a precision-engineered 2-jaw tool designed for safe, efficient removal of pilot bearings using compatible slide hammers. It fits both 5/8 x 18 and 3/4 x 16 thread rods, ensuring broad compatibility, and is built from durable materials for repeated use in professional and DIY automotive repair settings.

| ASIN | B004FDGU20 |

| Batteries Included? | No |

| Batteries Required? | No |

| Best Sellers Rank | #24,655 in Automotive ( See Top 100 in Automotive ) #25 in Puller Sets |

| Color | Black |

| Customer Reviews | 4.6 4.6 out of 5 stars (1,807) |

| Date First Available | June 4, 2012 |

| Included Components | PILOT BEARING PULLER ATTACH |

| Is Discontinued By Manufacturer | No |

| Item Package Quantity | 1 |

| Item Weight | 13.6 ounces |

| Item model number | 27059 |

| Manufacturer | Great Neck Saw |

| Material | Blend |

| Number Of Pieces | 1 |

| Part Number | 27059 |

| Power Source | hand_powered |

| Product Dimensions | 1 x 1 x 1 inches |

| Size | Pilot Bearing Puller Attachment |

| Special Features | 1 |

| Style | Pilot Bearing Puller Attachment |

J**R

Does the job!

I needed to remove the pilot bearing from my OG – LS1 for a clutch job. I’d seen several videos of people having success w/ the exact setup so went for it. The slide hammer was fine – no machining issues, came in a sturdy case with room for a few other tools. The case didn’t have a molded space for this particular tool but it fit in anyhow. The pilot bearing tool was good also the listed OEM . I did need to take a few corners down (the shiny areas) and disassemble the tool to get it inside the bearing – it was just a little too large to get in otherwise. Once in, a few hits and bam, it was out. There was another review on here that said the slide hammer and bearing puller tools did not work together. I’m not sure if maybe he had a mis manufactured part, but there are 2 sets of threads down in the bearing puller. A larger ¾” and a smaller 5/8” below that. I tried to get a pic of the lower thread set but it’s hard getting a photo inside a black hole.

D**S

Awesome tool, worked like a charm!

I had a pilot bushing comfortably resting in its home for 31 years, it did not want to come out. I borrowed a tool from the local parts store, no joy. Tried the trick of packing bread in the cavity and pounding with a bolt; yes, that's really a thing. That didn't work either. After buying this tool, I installed it on my slide hammer and after 3 or 4 whacks, out it came. I couldn't be happier. Too bad I'll probably never use it again, but it was worth every penny. Note that the threaded bore of the tool has two different thread diameters, my slide hammer was the smaller diameter and so I had to insert the hammer shaft in far enough to find the threads. I didn't realize this at first and had a moment of panic. Reading the description on the product page explains this, fyi.

E**R

Great slide hammer, punches above its cost class.

I bought just the hammer and slide and it’s kind of ridiculous how inexpensive this is for such a high quality slide hammer. If you have a need for a 5lb slide hammer (could probably use a heavier weight with it as well.) Then absolutely get this one, there’s no contest. It’s also got a high quality box and small shop print so it’s easy to store. Very lightweight overall as well. The sliding weight is of good quality and coated properly (way better grip and long lasting finish than a typical cheap galvanized weight) and the shaft is obviously a strong alloy of steel with a very polished finish.

S**E

Good Product

Good product, well made. The teeth of the puller are thick. So they may not fit into thin gaps. Such as the case with a Ford 400 pilot bearing (or Cleveland or Modified or Big Block). It removed the inner bearing section no problem but the sleeve "race" that gets pressed into the crank has thin removal ports that I'm sure Ford had a special tool for. I found a you tube video showing this tool being used to remove that pressed in part, but it did not work for me and went the hydraulic method which popped it quite easily. As in pack the cavity with grease find a socket the same diameter as the opening, reverse it, plug the 3/8 driver hole with an extension then tap the extension with a hammer, add more grease as needed. only with the cavity is completely full with the hydraulic principles work and push the part out. Works great but is messy.

H**R

Pilot bearing puller

Works as intended, heavy duty, nice tool, I added a rubber o ring around the fingers to keep them together it helps alot

G**Y

nice compact heavy built puller compatable with most slide hammers

If you already have a slide hammer this will most likely attach due to the two system thread pattern . This is a nice small puller for small ID bearings and seals in a blind hole that can't be pushed out from the back side. I used this to remove a double seal system in an outboard motor "lower unit bearing carrier". This 16 dollar tool will save you a hundred dollars worth of headaches removing just about anything from a blind hole. AAAAA++++++++++

S**K

Does the job

Slide hammer are apparently hard to find, this one came with a nice case. Probably paid more than I should have, but the job was way easier with it. I recommend it.

R**N

Well made

Good quality tool Worked great.

Trustpilot

1 week ago

1 month ago